Have you been told “Add some water, the concrete looks very hard”?

Is this right? Adding more water (Water Cement Ratio) at the site level to increase the concrete workability ???

Absolutely Not…

What is Water Cement Ratio?

Water Cement Ratio means the ratio between the weight of water to the weight of cement used in concrete mix.

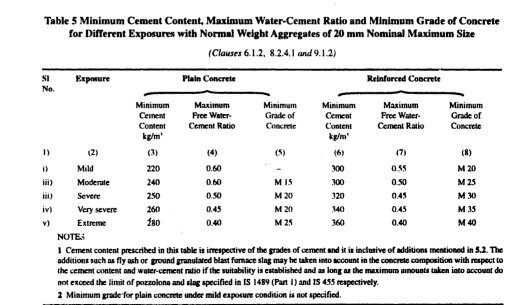

Normally water cement ratio falls under 0.4 to 0.6 as per IS Code 10262 (2009) for nominal mix (M10, M15 …. M25)

We all know that water cement ratio will directly affect the strength of concrete. Either it increases the strength if used in correct proportion or decrease it.

But have you ever think about it why we are using water if it has so much difficulty?

Role of Water in Concrete

Concrete is a macro content.

It contains micro ingredients such as cement, sand, fine aggregate & Coarse aggregate. In order to acquire high strength concrete which withstands up to our desired compressive strength, We need correct proportion of admixture to combine these materials.

Here comes the Water which will initiate this chemical process by adding 23%-25% of the cement volume. This initiates the chemical process and makes 15% of water cement paste also known as a gel to fill the voids in the concrete.

Effects of too much water in concrete

As stated above we need 23% of water to initiate the chemical process on cement.

Adding more water than this allowable Water cement limit will actually affect the strength.

If we keep on adding water to increase the workability then the concrete has lots of fluid materials where the aggregates will settle down. Once the water evaporated it leaves lots of voids in concrete which affects the concrete strength.

But if we follow the guidelines in order to maintain the strength of the concrete then it will affect the concrete workability and make us hard to handle and place them.

Wait a minute.

Do you know what is Workability Of Concrete?

Workability means the ability of concrete to handle, transport and placing without any segregation. The concrete said to be workable if it can be easily handled, placed and transported without any segregation while placing it in site.

That’s why we are using plasticisers & superplasticizers which will increase the workability without affecting the W/C Ratio.

How to calculate Water Cement Ratio? – W/C Ratio Calculation

We don’t actually calculate the Water Cement Ratio.

It is selected from various workability test based on the structural members, concrete strength, transportation, selection of aggregation etc.

At Site Level, we can make use of the below calculation for the nominal mix.

It is a guide so make your own judgment.

Water Cement Ratio IS 10262 (2009) Code Chart

Calculation of Water Quantity for Concrete

As you can see from the Chart, the W/C Ratio varies from 0.4 to 0.7 depending on exposure conditions.

If we need to calculate Water quantity for concrete, first find the cement content for the volume.

If we Assume the required cement volume as 50kg,

Required amount of water = W/C Ratio X Cement Volume

Therefore, Required amount of water = 0.5 X 50 kg = 25 litres / 50 kg cement bag.

For Design mix, the W/C Ratio will depend upon the workability, strength requirements.

In IS 10262-2009 ANNEX A. they have explained the process for design mix.

Hope that helps you.

Water Cement Ratio Test

We hope now you have a fair amount of knowledge on Water Cement ratio.

It is time to test this vital task. How to test water cement ratio?

We actually use Concrete Slump Test at the site level to check this workability & Consistency which we will discuss in the upcoming post.

Leave a comment if we missed anything…

Happy Learning 🙂